Industrial automated production refers to machine equipment, integrated intelligent production systems or processes (production, management processes) without the direct participation of no or fewer people, according to human requirements, after automatic detection, information processing, analysis and judgment, operation control , The process of achieving the desired goal. The use of automation technology can not only liberate people from heavy physical labor, some mental labor and harsh and dangerous working environment, but also expand human organ functions and greatly improve labor productivity. Through this solution, it can be practically applied to the automated production workshop of an unmanned factory-a piece of wood can be used to open, seal, and drill through the Industry 4.0 solution.

1. Capacity Matching

Approximately 100 sets of wardrobes will be processed in eight hours (Take a wardrobe without a door as an example, the data is for reference only)

2. Project Design

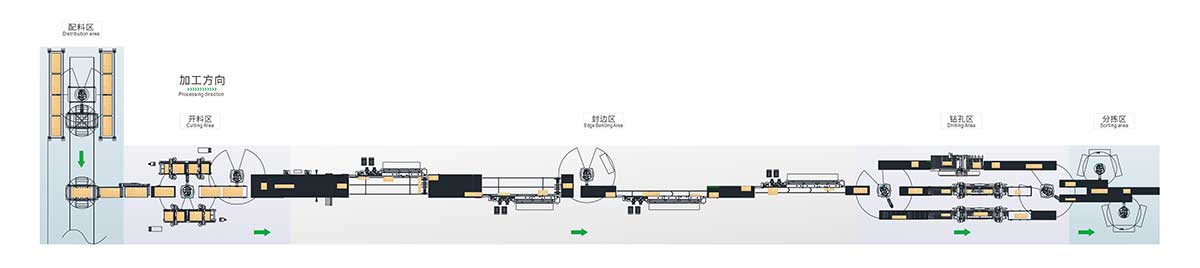

The segmented work cell is based on its relatively complete board-customized furniture software and stand-alone product system. By integrating the advantageous hardware and software resources in the industry and optimizing the configuration, we have developed a plan for a segmented automated production line for the board-type furniture industry. Work cell processing mode replaces the traditional production mode where panel furniture production workshops rely entirely on manual production organization and process flow, seamlessly connecting software, processing equipment, robots, and wire conveyors to achieve cabinet automatic processing from boards cutting to sorting. It can also be extended to connect to automatic packaging production lines and finished product warehouses in the future.

3. Work Cell Technical Solutions

Cutting work cell + automatic edge banding line + drilling work cell + automatic sorting line. Seamless connection of software, robots, and intelligent production equipment

(1) Cutting Work Cell

Intelligent and efficient cutting process, which can be expanded connect to the stereoscopic warehouse of raw materials, or to connect the edge banding line to the stereoscopic warehouse of finished products.

(2) Automatic Edge Banding Line

Intelligent and stable edge banding can not only accept the material from the cutting work cell, but also expand the subsequent drilling links.

(3) Drilling Work Cell

Intelligent high-speed CNC drilling processing can also be extended to connect edge banding lines and sorting stations.

(4) Automatic sorting line

Software, robots, and line conveyor seamlessly connect to realize intelligent sorting of customized furniture cabinets, and can also be expanded to connect drilling work cell or automatic packaging systems.

4. Software control

The FIN4.0 control system realizes the automatic control of the whole line linkage and circulation by interacting with the information of the scanning device, robots, buffer and other devices.

5. Advantages of extended full-line control

The integration of processing equipment, robots and conveying supporting devices, and the full-line control of the software, realize the automated line production of custom furniture from cutting to sorting and packaging, which greatly reduces the labor costs of furniture companies and improves processing efficiency. Strong scalability, which can be directly connected to the finished stereoscopic warehouse or automatic packaging system to further improve the automatic processing effect.

Conclusion

Automation≠Intelligent

Intelligentization refers to the attributes of things that can meet various needs of people under the support of technologies such as network, big data, Internet of Things and artificial intelligence. It integrates technologies such as the sensor Internet of Things, mobile Internet, and big data analysis to actively meet the production needs of the factory. The reason why it is active is that unlike traditional automation, it requires passive human operation and production. Compared with traditional automated production, intelligence is a comprehensive sublimation of media functions based on data. It means that through the application of intelligent technology, new media can gradually have similar human perception, memory and thinking ability, learning ability, adaptive ability and behavioral decision-making ability. In various scenes, human needs are the center, Actively perceive the outside world, make decisions and act on the random external environment through data processing and feedback in a manner similar to the human thinking mode and given knowledge and rules. If the board has a problem at a certain node, the intelligent production system will obtain the data in time and combine the solution to provide immediate feedback to it or put it aside first without affecting the overall production. In order to achieve artificial intelligence automatic production

Nanxing Machinery has been committed to the home equipment industry, and is also a pioneer of the "digital" factory 4.0, providing system cost-effective solutions for intelligent home production. Segmented automation or full-line automation solutions can greatly improve equipment performance and ensure production flexibility. When producing customized products, it can effectively shorten the delivery cycle, reduce labor, and improve production efficiency by the communication of equipment with real-time interactive software.